UHPH - Ultra high pressure homogenization

Our industry-leading systems provide the simultaneous sterilization and homgenization and of liquids, such as beverages, without causing any damage to the product or nutritional value.

This UHPH method is also referred to as 'Preservation' and production costs are often much lower than other sterilization techniques.

Our UHPH technology - Benefits

![]() An increase in product shelf-life through the inactivation of microorganisms with few effects on nutritional value.

An increase in product shelf-life through the inactivation of microorganisms with few effects on nutritional value.

![]() Mulitple temperature control systems enabling pre-cooling or pre-heating and post-cooling.

Mulitple temperature control systems enabling pre-cooling or pre-heating and post-cooling.

![]() Flow rates to 1000 l/hr (264 Gallons/hr).

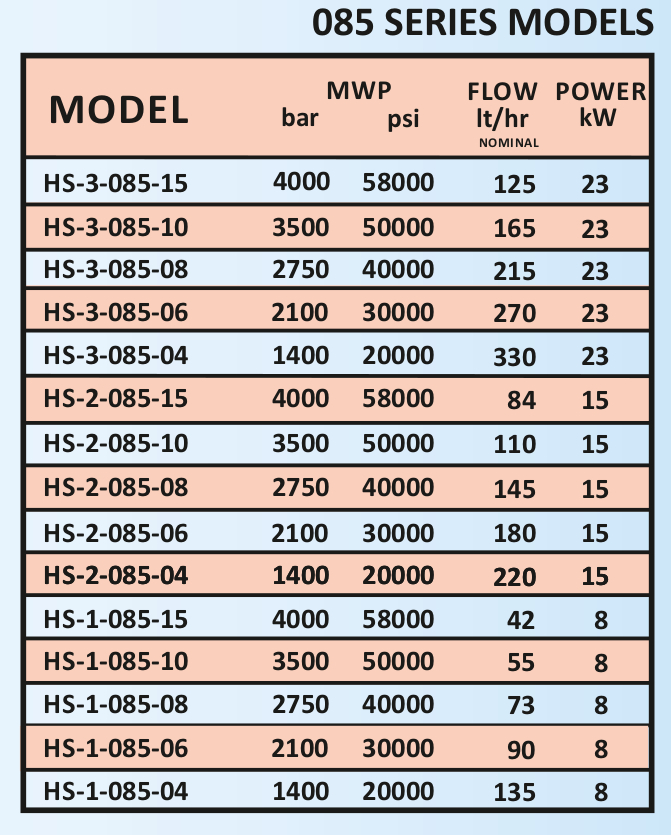

Flow rates to 1000 l/hr (264 Gallons/hr).

![]() Easy to operate, service and clean. CIP and SIP capability.

Easy to operate, service and clean. CIP and SIP capability.

![]() Industry-leading ultra high pressures up to to 60,000 psi (420 MPa, 4200 bar).

Industry-leading ultra high pressures up to to 60,000 psi (420 MPa, 4200 bar).

![]() Multiple processing valve options including micro channels (interaction chambers) and piston gap valves.

Multiple processing valve options including micro channels (interaction chambers) and piston gap valves.

![]() Power consumption is often lower than other processing technologies such as HPP / high hydrostatic pressure.

Power consumption is often lower than other processing technologies such as HPP / high hydrostatic pressure.