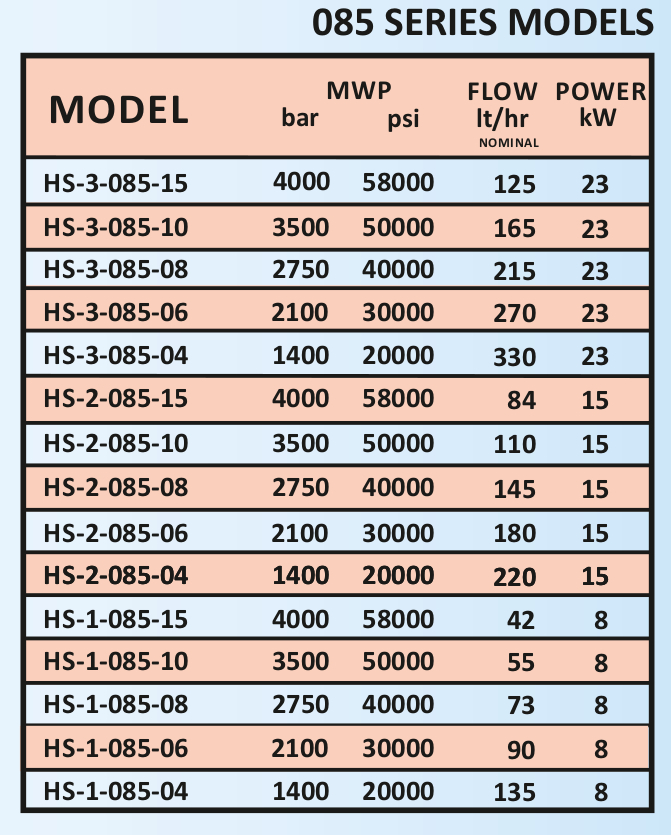

The 085 series of Homogenisation / Cell Disruption systems have been developed to meet the special requirements associated with Pharmaceutical, Biotechnology and Chemical industry processing applications.

UHPH - Production Homogenizers - features

![]() Multiple synchronised intensifiers for continuous high shear fluid processing with adjustable working pressures up to 60,000 psi (4200 bar).

Multiple synchronised intensifiers for continuous high shear fluid processing with adjustable working pressures up to 60,000 psi (4200 bar).

![]() Flow rates to 1000 l/hr with repeatable processing results.

Flow rates to 1000 l/hr with repeatable processing results.

![]() Easy to use, sterlize and maintain with lower ongoing operating costs than other systems.

Easy to use, sterlize and maintain with lower ongoing operating costs than other systems.

![]() CIP and SIP capability.

CIP and SIP capability.

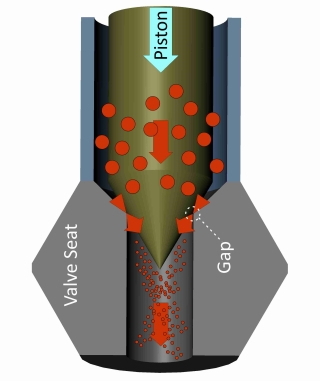

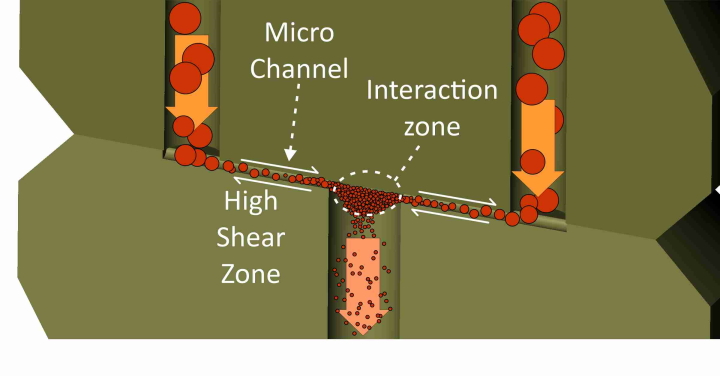

![]() Processing options of piston gap valves and micro channels (interaction chambers) to ensure optimised and customised processing to suit the application.

Processing options of piston gap valves and micro channels (interaction chambers) to ensure optimised and customised processing to suit the application.

![]() PLC based control logic with touch screen HMI interface with integral data logging of primary process parameters (pressures and temperatures) and communications options to third party systems.

PLC based control logic with touch screen HMI interface with integral data logging of primary process parameters (pressures and temperatures) and communications options to third party systems.

![]() Temperature control with heat exchanger options for system inlet, in process and outlet post process control.

Temperature control with heat exchanger options for system inlet, in process and outlet post process control.

![]() Corrosion resistant materials on all product wetted surfaces and ultra-high-grade corrosion resistant steels on main pressure containment elements.

Corrosion resistant materials on all product wetted surfaces and ultra-high-grade corrosion resistant steels on main pressure containment elements.

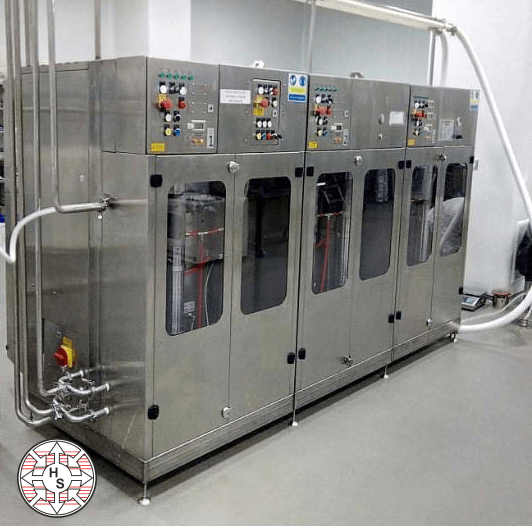

Production Homogenizer in pharmaceutical clean room

Homogenizing valves - Piston Gap and Micro-Channel Device (interaction chamber)

Production pilot scale Homogenizer - Pharmaceutical sector

Patented Construction

A unique intensifier design, referred to as Hyd-Lok, uses a hydraulic clamping mechanism, rather than bolts, to lock the intensifier assemblies together during operation. The ability to open the intensifier assembly at the push of a button without tools offers huge benefits for routine cleaning, inspection and maintenance, which can all be handled by the operator. Reassembly is automatically controlled to the correct closing force, eliminating the need to tighten bolts to proper torque and the possibility of galling.

The Hyd-Lok technique has recently been incorporated into some of the flow control valves and homogenising valve options, enabling our production systems to handle the most challenging requirements.

Reliability and durability

Robust electro-hydraulic drive system driving one or two (electronically synchronized) intensifiers. Each intensifier makes 2 to 12 strokes per minute, keeping seal and other component wear to a minimum, resulting in reliable operation and low cost of ownership.

Simple operation

Sophisticated PLC-based control and monitoring system, for simple push-button operation. This provides the operator with alphanumeric display with menu driven operation and fault diagnosis. The PLC digitally displays the system’s temperature and pressure, and has a communications port to allow connection to PCs or suitably interfaced data loggers.

Temperature Control

The nG11300 family includes sophisticated temperature control systems, enabling pre-cooling or pre-heating (as needed for processing liposomes), post-cooling, and maintaining the process section at a constant temperature (for products where this is critical to maintain smooth flow).

Easy to clean

Many applications demand that the equipment is thoroughly clean with no trace of previous use. Unlike other homogenizers, where plungers, intensifier, diaphragm etc. include dead areas that form condensate traps, the Hyd-Lok system has a steaming configuration to ensure total sterilization. When set to ‘steaming position’, sliding steaming cuffs operate through a number of paths while clamping, ensuring wetted surfaces are automatically exposed to temperature and vapour that remove all traces of contamination.

In addition, the principal wetted assemblies are extremely easy to disassemble, clean, inspect and reassemble.

Easy to Service

Scheduled maintenance is critical to proper and consistent operation of all high pressure homogenizers. The Hyd-Lok construction makes most routine maintenance tasks simple and within the scope of even basically trained operators. No longer does routine maintenance require specialist skills or even outside assistance; and such maintenance is accomplished quickly and easily without the protracted strip down associated with traditional high pressure designs.

For quick contact please click the 'Ask a Question' or 'Leave a message' tab.