7575 model in Pharmaceutical application with feed and discharge reservoirs.

Using our proven electro-hydraulic system and precise valve control system, homogenizers in the nG12500 are equally at home handling the most sophisticated applications and running small volume production.

Pilot - R&D Homogenizers - benefits and features:

![]() Single and twin intensifier versions, for continuous high shear fluid processing with flow rates up to 125 l/hr and pressures up to 4200 bar, 60,000 psi.

Single and twin intensifier versions, for continuous high shear fluid processing with flow rates up to 125 l/hr and pressures up to 4200 bar, 60,000 psi.

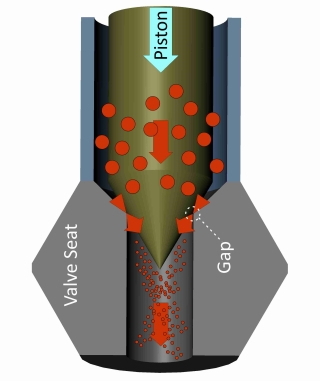

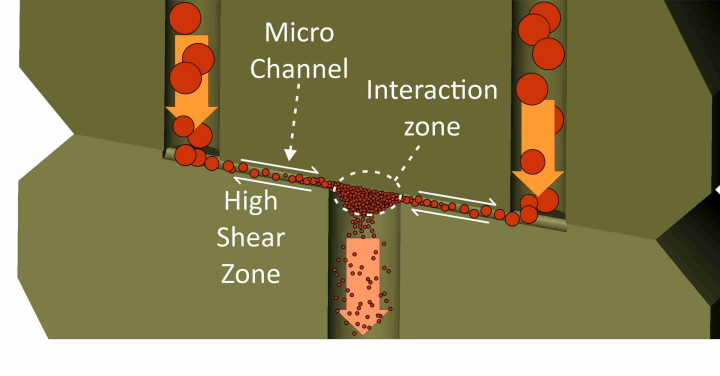

![]() Processing options of piston gap valves and micro channels (interaction chambers) to ensure optimised and customised processing to suit the application.

Processing options of piston gap valves and micro channels (interaction chambers) to ensure optimised and customised processing to suit the application.

![]() PLC based control logic now with touch screen HMI interface with integral data logging of primary process parameters (pressures and temperatures) and communications options to third parts systems.

PLC based control logic now with touch screen HMI interface with integral data logging of primary process parameters (pressures and temperatures) and communications options to third parts systems.

![]() Software and data logging suitable for production pharmaceutical applications.

Software and data logging suitable for production pharmaceutical applications.

![]() Temperature control with heat exchanger options for system inlet, in process and outlet post process.

Temperature control with heat exchanger options for system inlet, in process and outlet post process.

![]() Corrosion resistant materials on all product wetted surfaces and ultra-high-grade corrosion resistant steels on main pressure containment elements. Technical ceramics, PCD and tungsten carbide on critical high wear components.

Corrosion resistant materials on all product wetted surfaces and ultra-high-grade corrosion resistant steels on main pressure containment elements. Technical ceramics, PCD and tungsten carbide on critical high wear components.

![]() CIP and SIP capability.

CIP and SIP capability.

![]() Full documentation packs including DQ/IQ/OQ.

Full documentation packs including DQ/IQ/OQ.

![]() Easy to clean, sterlize and operate with lower than average ongoing ownership costs.

Easy to clean, sterlize and operate with lower than average ongoing ownership costs.

For quick contact please click the 'Ask a Question' or 'Leave a message' tab.

Processing valves - Micro-Channel Device (interaction chamber) and Piston Gap

For quick contact please click the 'Ask a Question' or 'Leave a message' tab.