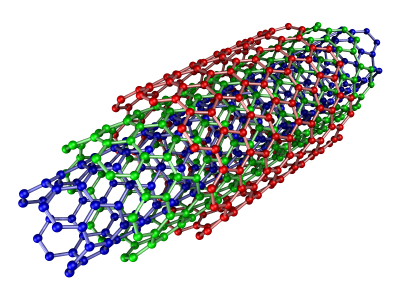

Carbon nanotubes (CNTs) are cylindrical molecules of rolled-up sheets of single-layer carbon atoms in the form of graphene. They can be single-walled (SWCNT) with a diameter of less than 1 nanometer or multi-walled. Their length can reach several micrometers. Carbon nanotubes exhibit many remarkable properties including exceptional tensile strength and superb electrical and thermal conductivity.

This page focuses on our High Pressure Homogenizers as a method of producting Carbon Nanotubes.

Carbon Nanotubes, to be used in applications, first need to be dispersed into a liquid medium which requires separation of the bundles, a process which is often carried out by sonication for a prolonged time - this technique is only suitable for low volumes.

Carbon Nanotubes - our High Pressure Homogenizers

![]() Our systems offer easier scalability for larger production volumes.

Our systems offer easier scalability for larger production volumes.

![]() Accelerated processing - so less resource demanding when compared to other techniques.

Accelerated processing - so less resource demanding when compared to other techniques.

![]() Our systems provide an efficient way to disperse and disaggregate CNT clusters with rep results.

Our systems provide an efficient way to disperse and disaggregate CNT clusters with rep results.

![]() Producing smaller particle sizes of uniform length in dispersions than other methods.

Producing smaller particle sizes of uniform length in dispersions than other methods.

![]() Possible increase in CNT concentration to above 50% after homogenization.

Possible increase in CNT concentration to above 50% after homogenization.

Our High Pressure Homogenizers - features

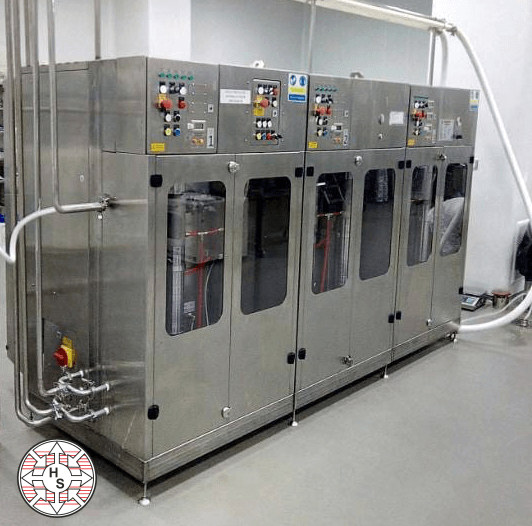

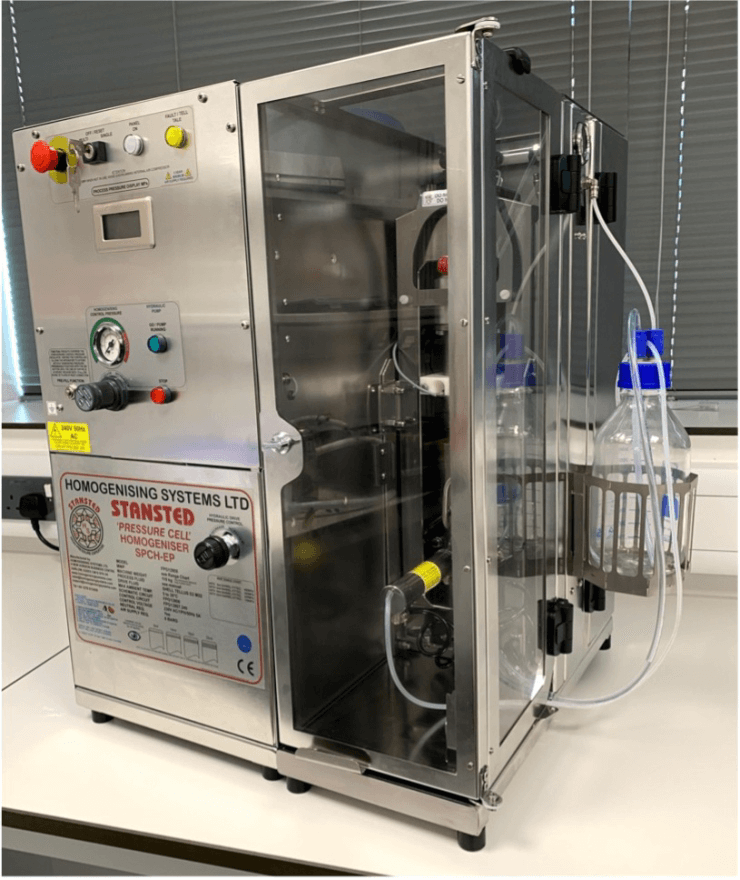

![]() Ultra high pressures to 60,000 psi (4200 bar) and processing from Lab R&D samples to flow rates in excess of 1000 l/hour.

Ultra high pressures to 60,000 psi (4200 bar) and processing from Lab R&D samples to flow rates in excess of 1000 l/hour.

![]() Exceptional processing versatility, systems control and scalability.

Exceptional processing versatility, systems control and scalability.

![]() Sophisticated temperature control including pre- and post-cooling or heating, to help preserve product integrity.

Sophisticated temperature control including pre- and post-cooling or heating, to help preserve product integrity.

![]() Easy to use, clean and service. Low on-going operating costs.

Easy to use, clean and service. Low on-going operating costs.

Please contact us now to discuss your Carbon Nanotube requirements.

Production scale system

Laboratory Homogenizer for R&D

Rotating single-walled zigzag carbon nanotube.

Triple-walled armchair carbon nanotube.

A scanning tunneling microscopy image of a single-walled carbon nanotube.