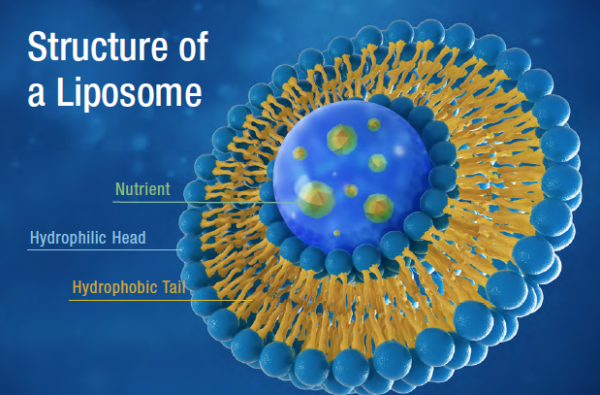

Liposomes can be used as a vehicle for administration of pharmaceutical drugs and nutrients as they are able to encapsulate and deliver the active ingredients to targeted areas.

This summary page focuses on mechanical high pressure homogenization (HPH) as provided by our class-leading homogenizing systems.

Liposomes - High Pressure Homogenizers

![]() Provide efficient reduction of vesicle size to achieve smaller vesicle sizes whilst narrowing the distribution.

Provide efficient reduction of vesicle size to achieve smaller vesicle sizes whilst narrowing the distribution.

![]() Provides an opportunity to load the liposomes, locating hydrophilic active substances within the aqueous vesicle core.

Provides an opportunity to load the liposomes, locating hydrophilic active substances within the aqueous vesicle core.

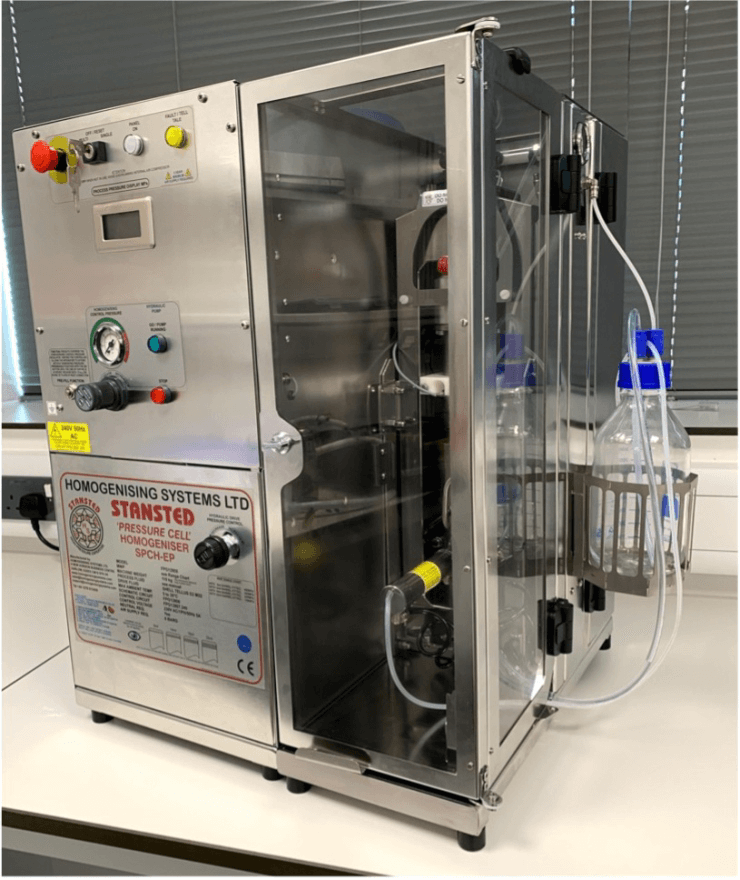

![]() Ultra high pressures to 4200 bar / 60,000 psi and processing from Lab samples 1m to 35ml up to process volumes up to 1000 l/hour.

Ultra high pressures to 4200 bar / 60,000 psi and processing from Lab samples 1m to 35ml up to process volumes up to 1000 l/hour.

![]() Scaleable systems with continuous processing and repeatable results. Easy to maintain and sterilize.

Scaleable systems with continuous processing and repeatable results. Easy to maintain and sterilize.

![]() Sophisicated options for temperature control - both pre-processing and post processing.

Sophisicated options for temperature control - both pre-processing and post processing.

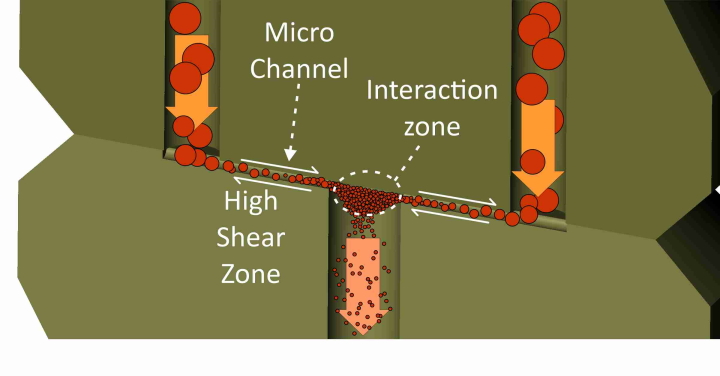

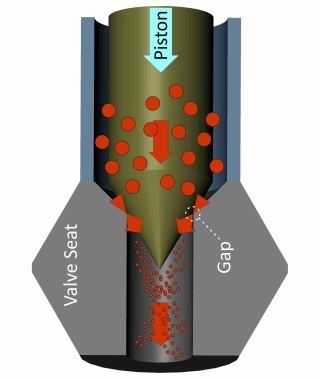

Micro-Channel Device (interaction chamber) and Piston Gap.

We offer, perhaps uniquely, interchangeable micro-channel devices (MCD) and piston gap (PG) processing heads for most of our Homogenizers. For liposome preparation both types can be effective - the choice will depend on experimentation and other factors.

Vesicle size reduction is a function of formulation, high pressure and valve type (MCD or PG) and formulation. Particle sizes from micron level to below 50 nm can be achieved.

Versatile bench top instruments - easy to use and clean.

For R&D and smaller production volume to 125 l/hr.

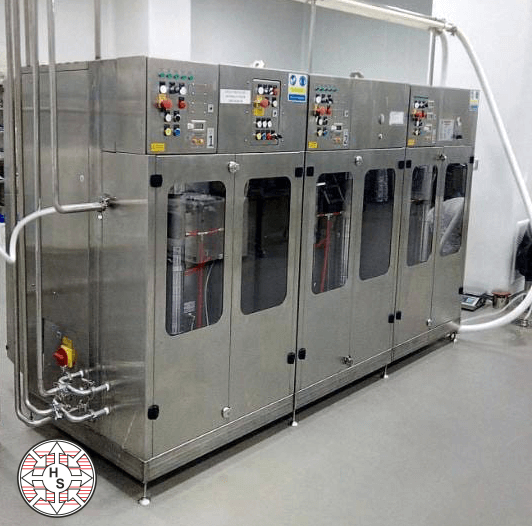

Full scale production systems with flow rates up to 1000 l/hr.