Nanocellulose extraction methods

The main methods are - acid hydrolysis, enzymatic hydrolysis and mechanical processes including our own High Pressure Homogenizers.

Nanocellulose - our High Pressure Homogenizers features

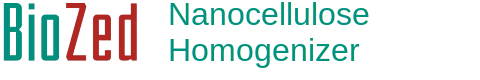

![]() Creating ultra-fine nanofibers whilst maintaining the original length.

Creating ultra-fine nanofibers whilst maintaining the original length.

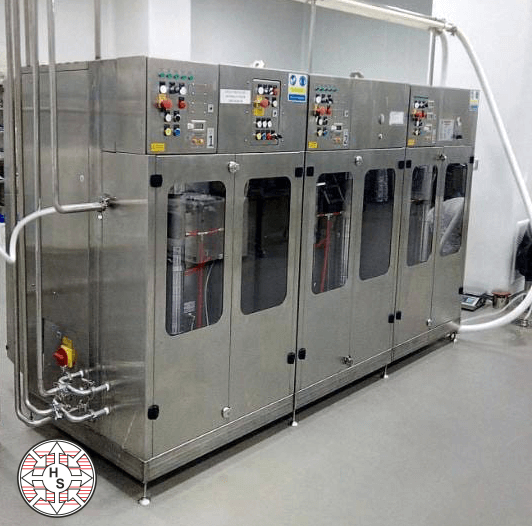

![]() Highly scalable systems - capable of creating Nanocellulose gels at production scale.

Highly scalable systems - capable of creating Nanocellulose gels at production scale.

![]() Smaller particles sizes, with tight distributions, when compared to other methods.

Smaller particles sizes, with tight distributions, when compared to other methods.

![]() Unqiue technology, and slower pump speed, lessens the risks of solid accumulation in the homogenizer.

Unqiue technology, and slower pump speed, lessens the risks of solid accumulation in the homogenizer.

![]() Very high pressures up to 60,000 psi (4200 bar) and processing from Lab samples to flow rates in excess of 1000 l/hour.

Very high pressures up to 60,000 psi (4200 bar) and processing from Lab samples to flow rates in excess of 1000 l/hour.

![]() Verstatile, controllable systems, with both micro-channel and piston gap processing options.

Verstatile, controllable systems, with both micro-channel and piston gap processing options.

Nanocellulose

Nanocellulose has many very attractive properties including excellent strength and stiffness, low density, high surface area and rich hydroxyl groups. Nanocellulose has multiple applications across sectors including material engineering, pharmaceuticals and cosmetics.

Nanocellulose is nano-structured cellulose that has been extracted from the cell wall, from a cellulose source material (e.g. wood pulp)

Please contact us now to discuss your requirements.

Nanocellulose is also referred to as:

CNF - cellulose nanofibers.

CNC or NCC - cellulose nanocrystal.

NFC - Nanofibrillated cellulose.

MFC - Microfibrillated cellulose.