Our industry-leading Homogenizers excel at producing particles sizes in the range from a few micrometers to a few nanometers with the following important characteristics:

![]() The smallest size - smallest ratio of droplet surface area to droplet volume.

The smallest size - smallest ratio of droplet surface area to droplet volume.

![]() Narrow distribution - most of the droplets at or below the target size with no "tails" on the distribution graph.

Narrow distribution - most of the droplets at or below the target size with no "tails" on the distribution graph.

Particle Size Reduction benefits

![]() Increased efficacy and bioavailability of the active active ingredient in the product.

Increased efficacy and bioavailability of the active active ingredient in the product.

![]() Improvements in product colour, taste, fluidity and chemical reaction.

Improvements in product colour, taste, fluidity and chemical reaction.

![]() Increased product stability resulting in increased shelf life.

Increased product stability resulting in increased shelf life.

![]() Elimination or minimization or elimination of contaminants.

Elimination or minimization or elimination of contaminants.

Our Homogenizer systems - benefits

![]() Temperature control systems to preserve product integrity.

Temperature control systems to preserve product integrity.

![]() Controllable operating pressures (up to 60,000 psi / 4200 bar) for maximum processing flexibility.

Controllable operating pressures (up to 60,000 psi / 4200 bar) for maximum processing flexibility.

![]() Low on-going ownership and maintenance costs. Highly reliable during all modes of processing

Low on-going ownership and maintenance costs. Highly reliable during all modes of processing

![]() Easy to use, clean, maintain and scale-up from Lab use to full production systems.

Easy to use, clean, maintain and scale-up from Lab use to full production systems.

![]() Efficient, repeatable production of nanoparticles with uniform particle sizes.

Efficient, repeatable production of nanoparticles with uniform particle sizes.

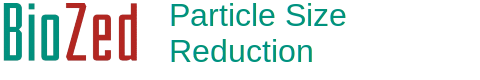

Up to 16 l/h. For R&D and small volumes - 1ml to 35ml samples.

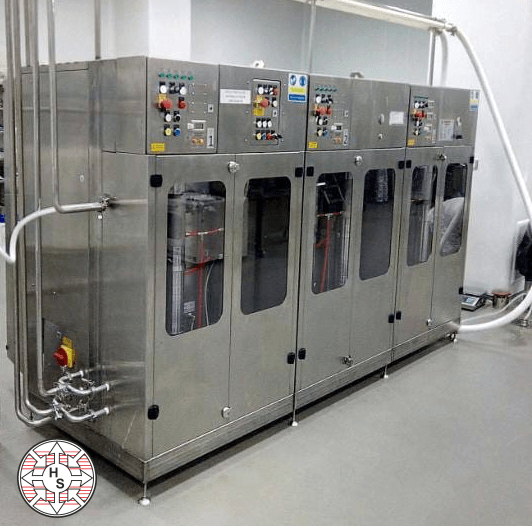

Pilot - smaller scale Production.

Up to 125 l/hr.

Up to 1000 l/hr (264 Gallons).