Polysaccharides are long chain polymeric carbohydrates composed of monosaccharide units joined by glycosidic bonds. They are increasingly used in the development of pharmaceuticals including in vaccine antigens, carriers for water-insoluble drugs and plasma expanders.

Polysaccharides - our High Pressure Homogenizers

![]() Industry-leading pressures to 4200 bar / 60,000 psi and processing from 1 ml to in excess of 1000 l/hour (264 USG).

Industry-leading pressures to 4200 bar / 60,000 psi and processing from 1 ml to in excess of 1000 l/hour (264 USG).

![]() Benefits may include low polydispersity, higher solubility at a neutral pH, reduced viscosity and easier for post processing purification.

Benefits may include low polydispersity, higher solubility at a neutral pH, reduced viscosity and easier for post processing purification.

![]() Our systems are easy to clean and maintain with low annual ownership costs.

Our systems are easy to clean and maintain with low annual ownership costs.

![]() Our systems are easy to scale-up from Lab R&D scale to full production units.

Our systems are easy to scale-up from Lab R&D scale to full production units.

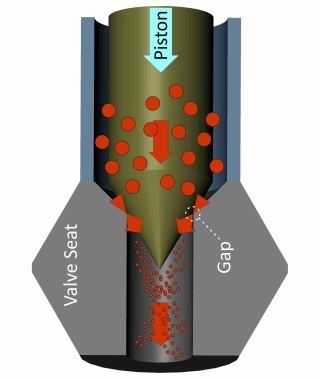

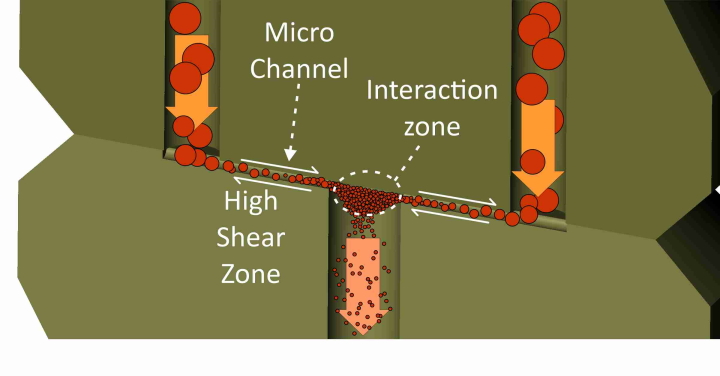

We offer interchangeable piston gap (PG) and microchannel devices (MCD) processing heads for our homogenizers - see below. We have polysaccharides processing customers using both types.

Contact us here to discuss your requirements

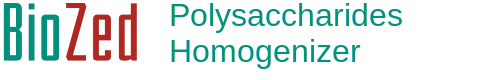

Pilot - Production Homogenizing System

Lab scale Homogenizer

Piston Gap and Micro-Channel Device ('interaction chamber').

Contact us here to discuss your requirements

3D structure of cellulose, a beta-glucan polysaccharide - Wikipedia